0086-533-7987888

0086-533-7987888

sale@wjcreator.com

sale@wjcreator.com

|

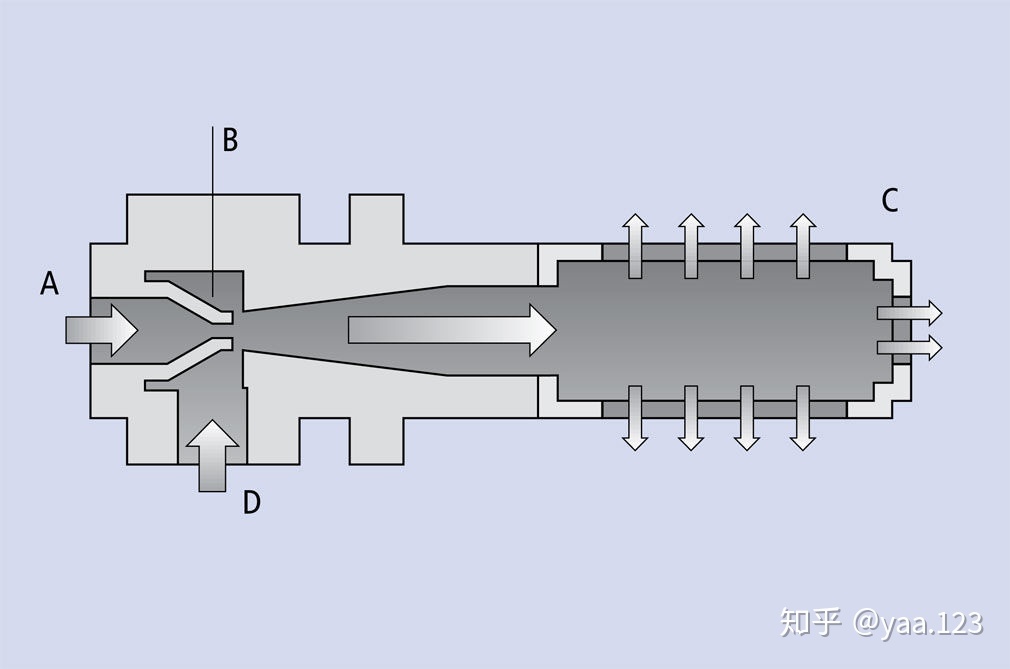

Venturi principle

working principle

The working principle of pneumatic vacuum generator is based on Venturi principle

Compressed air is sent into the vacuum generator (A)

As the section of the power nozzle (Venturi nozzle [B]) decreases, the compressed air flow rate increases. The dynamic pressure increases, while the static air pressure decreases at the same time.

Once the compressed air passes through the power nozzle, the accelerated air will expand and generate a vacuum.

Air is "sucked" into the vacuum generator through the vacuum interface (D)

The compressed air is discharged from the vacuum generator through the silencer (C) together with the "inhaled" air.

advantage

The vacuum generator working according to Venturi principle is especially suitable for very high acceleration environment

Vacuum suction can be controlled independently

The design of different types of vacuum generators for centralized and decentralized vacuum generation systems depends on the specific application

Various power levels suitable for different workpieces and applications

application

It can be used in all vacuum systems

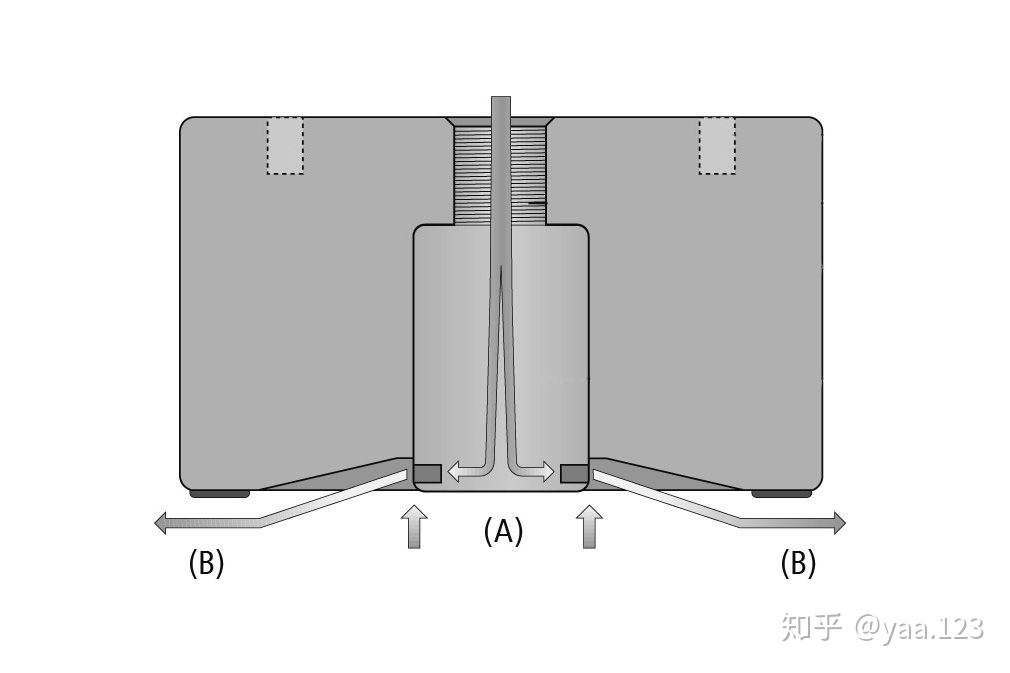

Bernoulli principle

working principle

Pneumatic operation with integrated vacuum generator

Compressed air is discharged from each hole in the suction cup, and the flow rate is significantly accelerated during the discharge process.

As the speed increases, the static pressure decreases and creates a vacuum (A) ("Bernoulli equation").

The air with faster flow rate is discharged from the side (B); An "air cushion" is created between the suspended vacuum suction cup and the workpiece.

The leakage is compensated by high flow rate, which means that porous workpiece can even be handled and separated.

Under the Bernoulli effect, the workpiece can be transported almost without contact.

The working mode of suspended vacuum sucker is based on Bernoulli principle.

advantage

Under the Bernoulli effect, the light and slow handling of thin sensitive workpieces can be realized with little contact

Safe separation of thin and porous parts

application

Handling very thin, highly sensitive or highly permeable workpieces

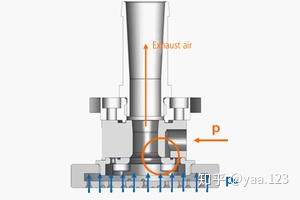

Konda principle

working principle

Pneumatic operation with integrated vacuum generator

According to the principle of Coanda, compressed air is introduced through annular gap, which accelerates the flow rate of compressed air.

The increase of the flow rate produces the "Coanda effect", and the discharged air flows with the protruding surface of the object.

The air flowing along the surface then generates suction ("entrainment") in the surrounding air.

advantage

Under the Konda effect, the adsorption rate is high and the air consumption is low (the working pressure only needs to be 1-5bar).

Large contact area and narrow vacuum opening prevent the workpiece from being sucked or damaged.

The adsorption area can also be partially fixed

Address: New Materials Pilot Zone of Science Town, Zibo city, Shandong Province, China

Tel 1: 0086-533-7987888

Email: sale@wjcreator.com

website: www.wjcreator.com